Fiberglass Pool Guide: Costs, Installation, Maintenance, and Pros & Cons

Outline:

1) What a fiberglass pool is, how it’s built, and how it compares to concrete and vinyl

2) True cost of ownership: purchase, installation, and lifetime expenses with examples

3) Installation timeline and site preparation, step-by-step from permit to first swim

4) Care, water chemistry, and seasonal maintenance for long-term durability

5) Pros, cons, design choices, environmental impact, and a practical conclusion checklist

What Is a Fiberglass Pool and Why It Matters

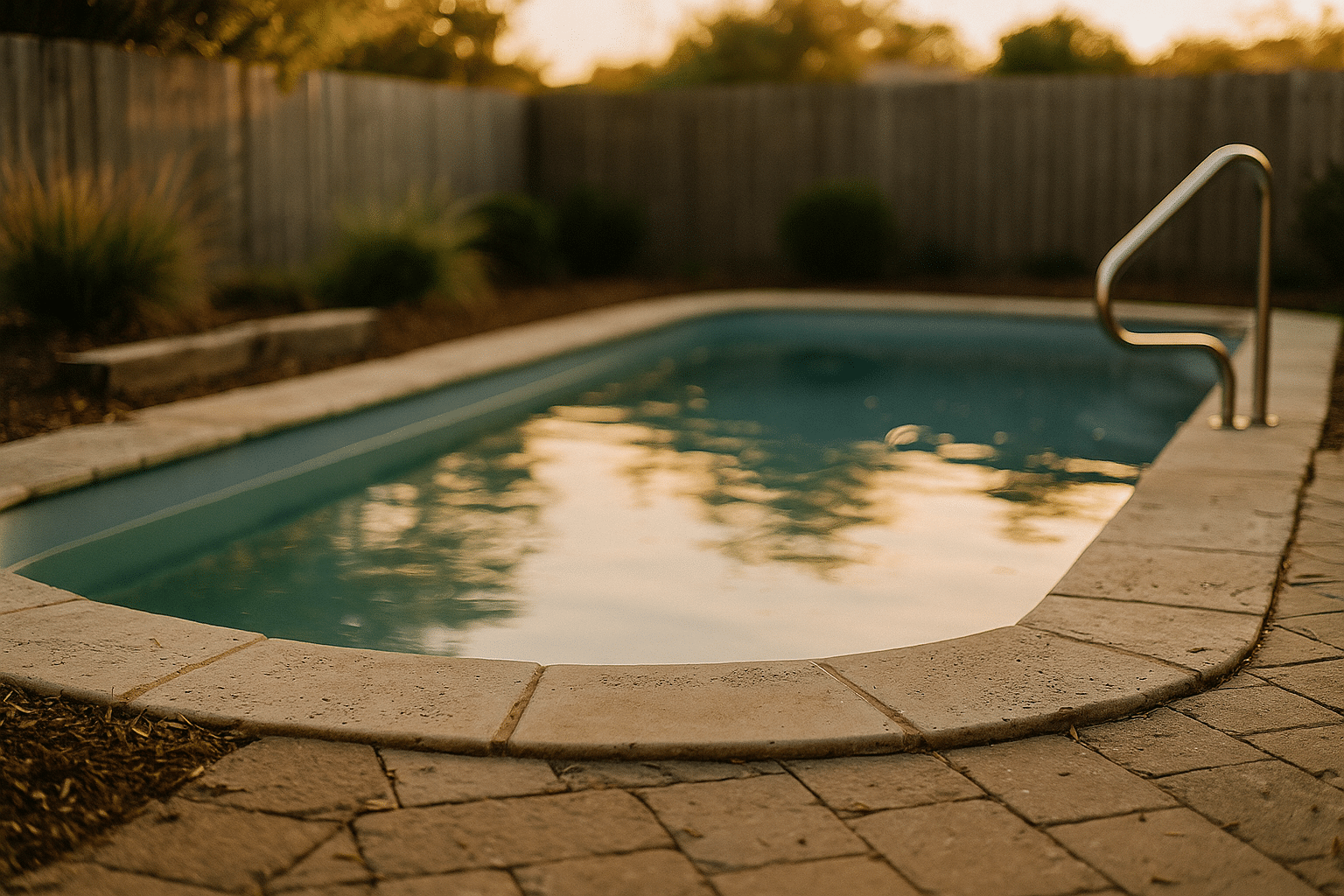

A fiberglass pool is a one-piece, factory-molded shell made from layers of fiberglass reinforced with resins and topped with a durable gelcoat. The shell arrives as a finished vessel that is craned into an excavated site, plumbed, and backfilled, which is why installation can be significantly faster than building a concrete structure on-site. The gelcoat surface is smooth and relatively nonporous compared with plaster, reducing areas where algae can cling and helping you use fewer chemicals over time. Because it is produced in a controlled environment, dimensional accuracy and finish quality are consistent across models, a detail appreciated by homeowners who prefer predictable timelines and outcomes.

Comparing materials helps frame expectations. Concrete pools are custom-shaped on-site, allowing virtually any geometry, depth profile, and feature integration. That creative freedom is balanced by longer construction windows, higher labor content, and surfaces that typically require more brushing and periodic resurfacing. Vinyl-liner pools, on the other hand, are budget-friendly to install and comfortable underfoot, yet liners can puncture and typically need replacement every 7–12 years, depending on care and usage. Fiberglass sits between these options: it offers a curated set of shapes and sizes—often including built-in steps, benches, and a tanning ledge—while emphasizing speed, low upkeep, and a finish that resists staining when chemistry is kept in range.

There are trade-offs. Transport limits impose maximum dimensions, so extra-long lap lanes or deep diving wells are less common in fiberglass formats. Repairs to the gelcoat are feasible but require skilled color matching to blend seamlessly. Site conditions also matter: high groundwater or unstable soils need mitigation (think dewatering wells and proper drainage) to keep buoyant forces in check. When matched to an appropriate site and maintained correctly, fiberglass shells can remain structurally sound for decades, delivering a straightforward ownership experience. For many households seeking an attractive, low-hassle swim space rather than an architectural statement, this material strikes a practical balance.

Key takeaways for quick orientation include:

– Factory-molded shell with smooth gelcoat that discourages algae attachment

– Faster installs than concrete, with integrated benches and steps common

– Limited size extremes due to shipping and crane logistics

– Lower routine brushing and chemical demand when water balance is maintained

True Cost of Ownership: Purchase, Installation, and Lifetime Expenses

Budgeting for a fiberglass pool means looking beyond the shell price to a full project scope. A typical shell may range from approximately $12,000–$30,000 depending on size and complexity, while turnkey installations commonly span $35,000–$85,000 or more, shaped by region, access, soil conditions, and selected features. A comparable concrete project often lands in the $60,000–$120,000 bracket, with vinyl-liner builds frequently between $28,000–$55,000. Those numbers shift with decking, water features, automation, lighting, and heating systems, which can add several thousand dollars each. Permitting, engineering (where needed), and inspections add modest but real costs and should be included early in planning.

Hidden or variable line items are where many budgets drift. Crane time can vary with reach and neighborhood constraints. Excavation bids depend on the haul distance and whether you encounter rock. Backfill materials—commonly clean, angular gravel—are priced by volume and locality. Electrical bonding, dedicated circuits for pumps and lights, gas or electric service for heaters, and water delivery (if a hydrant or well fill is not practical) each represent distinct work orders. Safety features, such as fences, alarms, or compliant covers, are often required by code and can meaningfully influence the total.

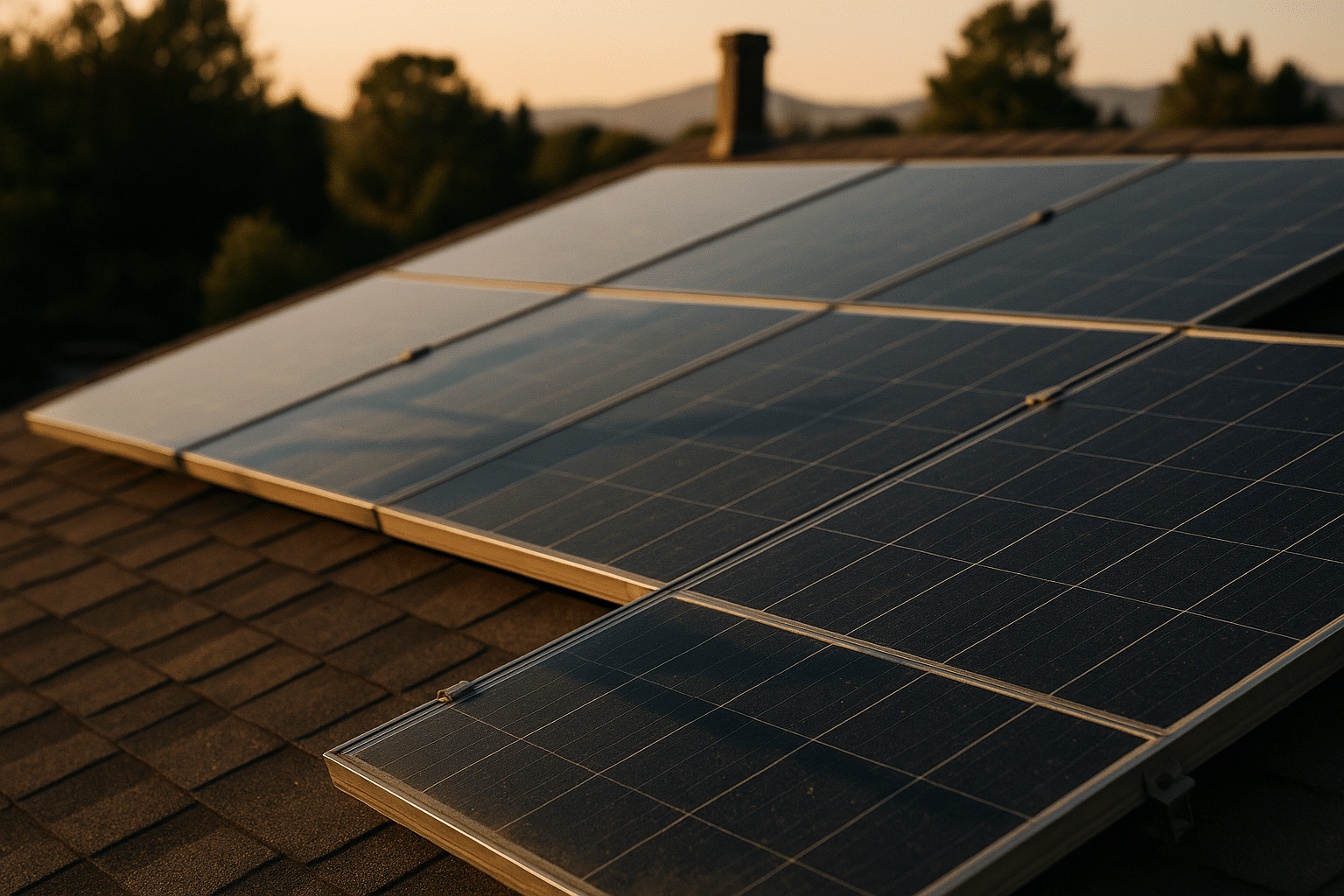

Operating costs are comparatively gentle with fiberglass. The smoother gelcoat typically reduces brushing labor and chemical consumption, and many owners report year-over-year chemical costs in the $200–$600 range per standard residential pool when chemistry is monitored consistently. Electricity varies with pump type, runtime, and region; a variable-speed pump can trim energy demand substantially versus a single-speed unit, with monthly consumption often in the low hundreds of kilowatt-hours under optimized schedules. Heating, the largest discretionary expense, depends on climate and cover usage: a solar blanket can cut heat loss and evaporation by 50–70%, while a heat pump’s coefficient of performance commonly falls around 4–6 in mild conditions.

Looking at the decade scale helps illustrate differences among materials. Concrete pools typically need resurfacing at multi-year intervals, a project that can run into the five figures depending on size and finish. Vinyl liners usually require replacement within 7–12 years, with costs tied to thickness, pattern, and labor. Fiberglass gelcoats, when kept within water balance targets, can avoid major surface overhauls for extended periods, though occasional spot repairs or polish work may be warranted. To keep planning grounded, assemble a pro-forma that includes:

– Initial build (shell, labor, crane, excavation, backfill, utilities, permits)

– Decking and hardscape

– Safety measures and code compliance

– Annual chemicals, electricity, and optional service visits

– Long-term surface or liner renewal reserves

Installation Timeline and Site Preparation: Step-by-Step

One of fiberglass’s calling cards is speed, but that speed relies on professional site work and steady coordination. A typical sequence starts with permitting and utility locates, which can require 2–6 weeks depending on the municipality. During this window, contractors confirm access routes for trucks and the crane, verify soil and groundwater conditions, and fine-tune elevations to integrate drainage paths and future decking. Once permits are in hand, excavation begins: crews shape the hole to match the shell template, accounting for the gravel base and allowing generous working room around the perimeter for plumbing, backfill, and setting the beam.

The base is usually a compacted bed of clean, angular stone. This creates a level, stable cradle that drains efficiently and discourages voids under the shell. With the crane on-site, the shell is rigged and lowered into place, then checked in multiple axes for level and alignment with benchmarks. Plumbers immediately begin setting returns, skimmers, and suctions, pressure testing lines before backfilling. Backfill and water fill typically proceed together in “lifts,” keeping the water level inside the shell roughly even with the backfill height outside to control hydrostatic pressure and maintain shape integrity.

Groundwater management is crucial. Many projects incorporate a dewatering well or sump pipe, allowing contractors to pump down water if needed during installation and for any future maintenance that requires partial draining. Bonding and electrical work tie together metallic components to a common grid for safety, and inspections confirm compliance. The top perimeter—often called the bond beam—sets the stage for coping and decking, which can be poured concrete, pavers, or stone. Final grading shapes surface runoff away from the pool, while soft landscaping restores the site.

From excavation to fill, the active construction phase can be 1–3 weeks under smooth conditions, with total calendar time stretching based on permit timing, weather, and scheduling. Homeowners can help avoid delays by confirming driveway load capacities, clearing access paths, and preselecting finishes. Keep an eye on quality markers:

– Properly compacted, level stone base without organic material

– Even backfill lifts matched to water level inside the shell

– Verified plumbing pressure tests and electrical bonding

– Documented groundwater strategy (sump or well) and drainage slopes

Care, Water Chemistry, and Seasonal Maintenance

A fiberglass pool is often chosen for low-touch care, and that promise holds when water chemistry stays within target ranges. Aim for a pH of roughly 7.2–7.6 and total alkalinity of about 80–120 ppm to stabilize pH swings. Calcium hardness needs less elevation than in concrete pools, with many fiberglass manufacturers recommending around 175–225 ppm to minimize scaling risk without encouraging precipitation. If you chlorinate manually or via a salt system, keep free chlorine in alignment with cyanuric acid (CYA), often 30–50 ppm for unstabilized chlorine and higher targets in very sunny regions. For salt pools, common operating ranges cluster near 3,000–3,500 ppm; always verify the particular controller’s specification.

Routine tasks are straightforward. Skim debris, empty skimmer and pump baskets, and brush smooth surfaces weekly with a soft, non-abrasive brush. Because gelcoat is slick, algae adhesion is reduced, yet stagnant corners still benefit from periodic attention. Vacuum as needed, whether manually or with a robotic cleaner designed for fiberglass finishes. Test water at least weekly during the swim season and after heavy rainfall, heat waves, or large bather loads. Adjustments are typically modest: raising alkalinity with bicarbonate, nudging calcium if fill water is soft, or dosing a sequestrant if metals are present to prevent stains.

There are a few don’ts worth noting. Avoid placing chlorine tablets directly in the skimmer where concentrated flow can etch or discolor surfaces. Do not drain the pool without professional guidance; groundwater can buoy the shell if external pressure exceeds interior water weight. If a partial drain is necessary to correct high CYA or total dissolved solids, a contractor can evaluate the sump, soil moisture, and timing to do it safely. For stain prevention, manage metals in well water and watch for leaves or organic debris sitting too long, especially in warm temperatures.

Seasonal playbooks keep things predictable. In cold climates, closing typically involves balancing chemistry, adding winter algaecide, lowering water as directed by your equipment setup, blowing out and plugging lines, and installing a safety cover. In spring, remove debris carefully to avoid dragging grit across the gelcoat, rebalance chemistry, purge antifreeze, and restart circulation with a filter clean. In warm climates, evaporation control with a solar cover can save significant water and energy. A concise checklist helps:

– Weekly: test pH/FC, skim, brush, empty baskets

– Monthly: verify alkalinity, calcium, CYA; inspect seals and unions

– Quarterly: deep-clean filter, assess pump schedules, polish waterline if needed

Pros, Cons, Design Choices, Environmental Impact, and Your Decision Checklist

The appeal of fiberglass pools rests on a practical proposition: attractive designs with integrated features, delivered quickly, and maintained with less effort than many alternatives. Built-in benches, loungers, and entry steps come molded into the shell, and many models include a shallow lounging shelf that doubles as a play zone for kids or a place to cool off. Depth profiles often target family use rather than diving, with common maximum depths under eight feet, and lengths suitable for fitness-minded swimming are available in several streamlined layouts. Color choices and subtle surface sparkles can shape the water’s appearance, yet the real value is the consistently smooth gelcoat that is kind to skin and simpler to keep clean.

There are reasonable cautions. Highly customized shapes, integrated vanishing edges, or complex multi-level geometry are more naturally handled by concrete builds. Transport and crane access can constrain shell size, and tight urban lots may need creative logistics or smaller formats. Surface blemishes can occur from poor chemistry or abrasion, though they are usually manageable with correct care. For resale, pools can influence property value differently by region; local demand, yard size, and maintenance perceptions shape outcomes more than any single specification. Insurance and utility costs should be understood up front, and homeowners should confirm code requirements for barriers, alarms, and anti-entrapment devices.

Environmentally, fiberglass can support efficient operation. Variable-speed pumps routinely cut energy consumption by 50–70% versus full-speed operation when schedules are optimized. A heat pump paired with a solar cover can stretch the season while reducing energy intensity compared with gas-only strategies. Because fiberglass surfaces do not require frequent acid washing and avoid liner replacements, material turnover over time may be lower than in other formats. Water-saving habits—covering the pool, fixing leaks promptly, and minimizing splash-out—deliver year-round benefits. Plants and permeable hardscapes around the deck can improve drainage and soften heat buildup on hot days.

As you weigh the decision, assemble a concise, fact-driven plan:

– Define goals: family recreation, fitness laps, quiet retreat, or a mix

– Map site constraints: access, setbacks, sunlight, trees, utilities, groundwater

– Establish budget tiers for base install, features, and contingencies (10–15%)

– Compare life-cycle costs versus concrete and vinyl over 10–15 years

– Confirm groundwater strategy, dewatering access, and drainage grading

– Review warranties separately for structure and surface, and note exclusions

– Request a startup orientation and a written maintenance schedule

Conclusion: If your priority is a streamlined installation, smooth surfaces that simplify upkeep, and a curated menu of shapes that cover most family and fitness needs, a fiberglass pool can be a well-regarded option. Approach the project as you would a home addition: validate site conditions, pressure-test the budget, and choose contractors who document steps and communicate clearly. With those elements in place, you can look forward to a backyard water space that fits daily routines without turning weekends into a second job.