Solar Panels Explained: Types, Efficiency, Costs, and Installation Tips

Outline and Roadmap: What You’ll Learn and Why It Matters

Solar panels promise quiet, steady power from sunshine, but good decisions start with clear expectations. This article moves step by step—from the big picture to the nuts and bolts—so you can map solar to your home, your climate, and your finances. By the end, you’ll understand where different technologies fit, how systems perform in real weather, what drives total cost and payback, and how to approach installation safely and confidently. Consider this your compass before you commit.

Here’s the journey we’ll take, and how each stop helps you make an informed choice:

– Types and use-cases: We’ll compare common panel technologies, discuss efficiency ranges, temperature behavior, weight, and aesthetics, and match each type to typical roofs and climates.

– Efficiency in the real world: We’ll translate lab ratings into actual output by looking at temperature, shading, orientation, and inverter choices—and we’ll quantify the impact with practical examples.

– Costs and payback: We’ll break down installed price per watt, incentives, financing paths, and long-term maintenance, then build a simple, transparent payback estimate you can adapt.

– Installation and safety: We’ll cover roof readiness, attachment methods, wiring basics, permitting, inspection, and maintenance so you know what to ask professionals and what to watch for.

Who benefits most from this guide?

– Homeowners evaluating a rooftop project and wanting credible numbers rather than buzzwords.

– Property managers weighing solar on carports or flat roofs seeking durability and predictable returns.

– Small businesses targeting lower operating costs and a hedge against energy price volatility.

– Curious learners who want rigor without jargon.

Before you begin, gather a recent year of utility bills, note your roof’s age and material, and take a quick look at nearby shade sources (trees, chimneys, neighboring buildings). With those in hand, the comparisons ahead will immediately feel more concrete. Finally, keep local codes and permitting timelines in mind; they shape schedules and sometimes equipment choices. With this roadmap, let’s unpack the technologies first—because picking the right panel narrows the field and strengthens every decision that follows.

Solar Panel Technologies and Where Each Shines

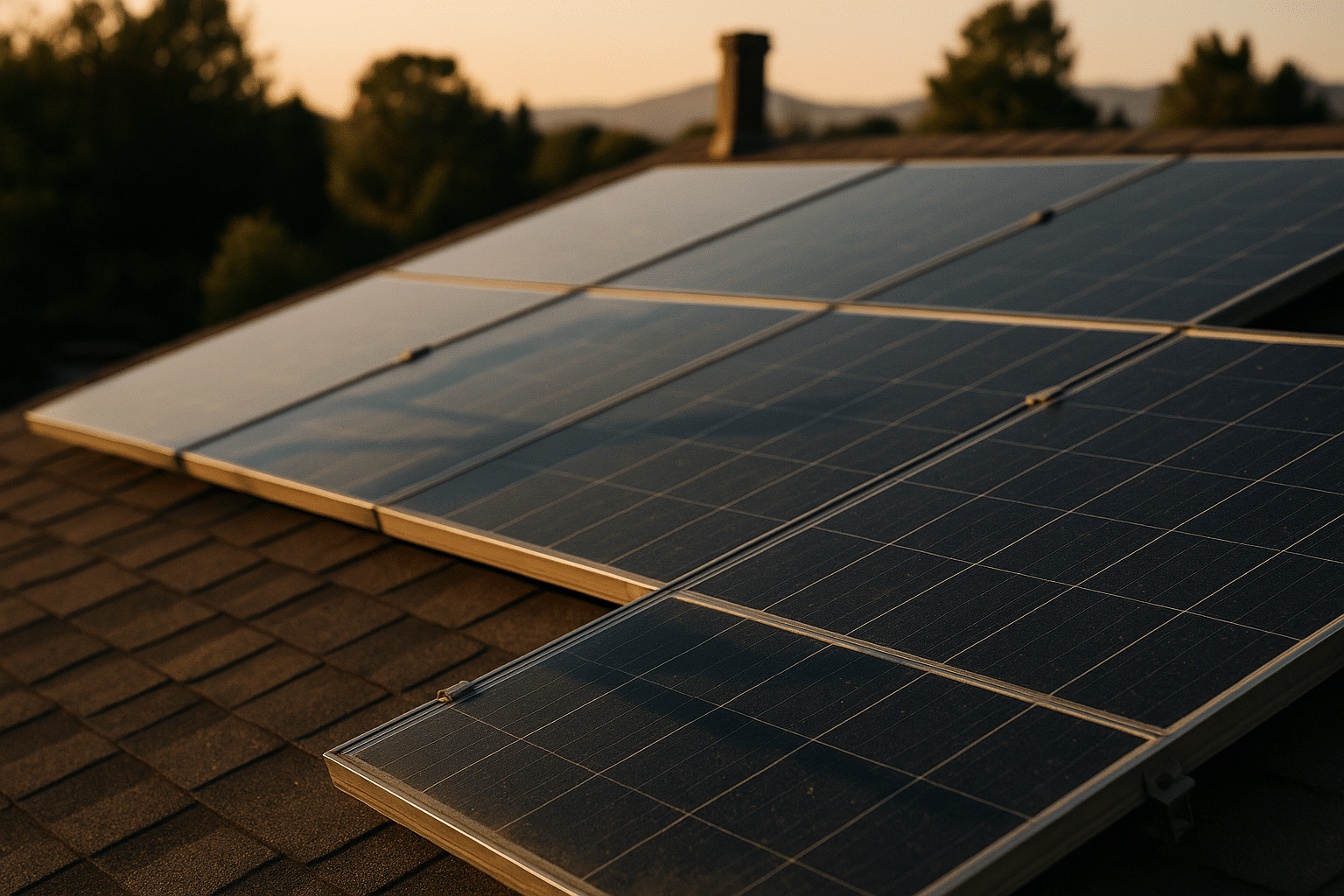

Most residential and light commercial arrays use one of three families: monocrystalline silicon, polycrystalline silicon, and thin-film. Each brings distinct trade-offs in efficiency, temperature behavior, weight, flexibility, and cost. Monocrystalline modules are typically the most energy dense, with many models advertised in the 20–23% efficiency range. Their cells are cut from single-crystal ingots, which helps electron flow and yields higher power per square foot—handy when roof space is limited. Polycrystalline panels, formed from multiple crystal grains, usually land around 16–18% efficiency. They often cost less per watt and still deliver reliable, long-lived performance. Thin-film panels—including amorphous silicon, cadmium telluride, or copper indium gallium selenide—tend to be lighter and can handle diffuse light well, but they often sit in the 10–13% efficiency band on rooftops, meaning they require more area for the same power.

Temperature coefficient is a quiet but important spec. As cell temperature rises, power output drops. Many monocrystalline and polycrystalline modules list coefficients around −0.30% to −0.45% per °C above 25°C. That means a hot summer noon can trim several percent off rated output, especially on dark roofs with limited airflow. Thin-film technologies sometimes handle heat more gracefully on a percentage basis, but their lower absolute efficiency can still require larger surfaces to match energy yield. If your climate runs hot, prioritize racking that promotes ventilation and consider lighter-colored roof surfaces or standoff mounts to reduce heat soak.

Aesthetics and form factor also matter. Some modules feature uniform dark faces and concealed busbars for a streamlined look; others show distinct cell patterns that some homeowners don’t mind and others prefer to avoid. Thin-film laminates can blend on certain metal roofs and add minimal wind load. Lifespan-wise, crystalline panels commonly carry performance warranties of 25 years, with typical degradation around 0.3–0.6% per year after the first year. Thin-film warranties vary more, so read the fine print on power retention and environmental certifications.

Choosing among these families becomes easier with a few rules of thumb:

– Tight roof space and a premium on kWh per square foot: favor high-efficiency monocrystalline.

– Moderate budgets with ample roof area: polycrystalline can provide strong value per watt.

– Weight-sensitive structures or specialty surfaces: thin-film may fit where framed modules don’t.

There’s no one-size-fits-all answer; match the panel to your roof geometry, climate, and visual goals. Next, we’ll translate the spec sheet into street-level performance so you can forecast energy with confidence.

Efficiency, Performance, and Real-World Output

Panel labels are tested under Standard Test Conditions (STC): 1,000 W/m² irradiance, 25°C cell temperature, and a specific spectrum. Your roof rarely sees those conditions. A more realistic yardstick is the Nominal Operating Cell Temperature (NOCT) rating, often around 44–48°C at 800 W/m² and 20°C ambient with wind. As cells heat above 25°C, that −0.30% to −0.45% per °C temperature coefficient quietly chips away at output. In practice, a rooftop array might run 10–20% below its STC rating during sunny, warm afternoons—even though those hours still deliver the day’s biggest kWh total.

Orientation, tilt, and shading are the next big levers. South-facing arrays (in the northern hemisphere) with tilt angles near local latitude maximize annual production, but roofs rarely line up perfectly. East- and west-facing systems still perform well, often losing only 10–20% annually versus south when designed thoughtfully, and they can better match morning or late-day household loads. Shading from trees, chimneys, or vent stacks can cause disproportionate losses because shaded cells limit current across a string. Bypass diodes and module-level power electronics reduce the penalty, but it’s always smarter to prune or relocate shade sources where possible.

Inverter architecture also shapes output. String inverters are economical and efficient when shading is minimal and roof planes are uniform. Microinverters or DC optimizers let each panel operate closer to its own maximum power point, mitigating mismatch and partial shading losses while enabling detailed monitoring. Performance ratio (PR)—the ratio of actual production to the theoretical output under site irradiance—captures all these real-world effects. Well-designed residential systems often achieve PR values of 0.75–0.85 over a year.

To ground this, consider annual specific yield (kWh per kWdc):

– Sunny, arid regions can reach 1,500–1,900 kWh/kWdc-year on well-oriented rooftops.

– Temperate climates commonly land near 1,000–1,400 kWh/kWdc-year.

– Cloudier, high-latitude areas may see 800–1,100 kWh/kWdc-year, with seasonal swings.

Degradation matters too. Modern crystalline panels often lose about 2–3% in the first year (“light-induced degradation”), then settle into 0.3–0.6% annually. Over 25 years, that still leaves a substantial share of original capacity. Maintenance—keeping modules free of heavy dust, pollen, or snow—helps preserve PR, though light dirt often has a modest impact and washes off with rain. Finally, don’t overlook grid or battery interfaces: exporting excess energy under fair net billing, or storing afternoon peaks for evening use, can improve the value of each kWh even if it doesn’t change total production.

Costs, Incentives, and Payback Math You Can Actually Use

Installed costs vary by location, roof complexity, labor rates, and equipment choices, but a common residential range in many markets lands around $2.50–$4.00 per watt before incentives. A 6 kW system, for example, might price at $15,000–$24,000 pre-incentive. Soft costs—design, permitting, interconnection, overhead, and customer acquisition—often rival hardware costs. Roof structure (steep pitches, multiple planes, tile or slate materials) can nudge labor and racking expenses upward. Ground mounts demand posts, trenching, and sometimes grading, which add balance-of-system costs but enable ideal orientation and airflow.

Incentives can reshape the ledger. Tax credits reduce upfront expense, while rebates lower out-of-pocket cost at purchase. Net energy metering or net billing programs set how exported power is credited; some credit at retail rates, others at avoided or time-of-use values. Performance-based incentives pay per kWh generated. Grants and low-interest loans may support schools, nonprofits, or rural properties. Always confirm eligibility windows, stepdowns, and documentation needs; missing a deadline can erase a meaningful chunk of value.

To estimate payback, start with annual production. Suppose a 6 kWdc array in a temperate climate produces 1,200 kWh/kWdc-year: that’s about 7,200 kWh annually. If your all-in electricity rate (energy plus fees) averages $0.20/kWh, the avoided cost is roughly $1,440 per year before any changes in rates or export credits. Subtract modest operations and maintenance—panel washing as needed, monitoring subscriptions if applicable, and inverter replacement perhaps once in 10–15 years for certain architectures. With a post-incentive net cost of, say, $12,000, simple payback would be around 8–9 years, with internal rate of return shaped by local rates, escalation, and policy stability.

What moves the payback needle?

– Higher utility rates or steep time-of-use peaks improve solar’s savings impact.

– Favorable export credits accelerate returns for surplus afternoon production.

– Right-sizing the array to on-site consumption increases self-use, boosting value.

– Efficient appliances and demand shifting (laundry or EV charging midday) amplify savings without adding panels.

– Durable roofs and minimal shade limit performance surprises and extra costs.

Beyond finances, solar can reduce carbon intensity of your electricity. In regions where grid electricity averages 0.4–0.9 kg CO₂ per kWh, a 7,200 kWh/year system avoids several metric tons of emissions annually. While environmental benefits don’t show up on a balance sheet, they can matter for property value, tenant marketing, or procurement goals. Treat them as a parallel return that complements the dollars-and-cents case.

Installation Tips and Final Takeaways

Smart installations begin before any hardware arrives. First, confirm the roof is solar-ready: remaining roof life should ideally exceed 20 years, or replacement should happen before racking goes in. Structural conditions matter; a professional should check rafters, decking, and fastener pullout strengths, especially on older homes or in snow and wind zones. Layouts should avoid obstructions that throw shadows and maintain required setbacks for fire access, which vary by jurisdiction. Penetrations must be flashed and sealed to the roofing manufacturer’s standards to prevent leaks across decades, not seasons.

Electrical design deserves equal attention. Conductor sizing, overcurrent protection, and rapid shutdown requirements evolve with code cycles, and compliant equipment labeling speeds inspections. Whether you choose a single string inverter, DC optimizers, or microinverters, plan for serviceability and ventilation. Group components where they’re protected from direct sun and rain, mind clearances, and route exposed conduit neatly along ridgelines or eaves. If batteries are part of the plan, ensure dedicated clearances, ventilation per code, and coordination of shutdown and backup circuits so critical loads (refrigeration, lighting, networking) are clearly identified.

Permitting and interconnection timelines can surprise first-time buyers. Proactive communication with your authority having jurisdiction (AHJ) and utility can clarify plan set expectations, meter upgrades, or service panel changes. Some utilities require production meters or separate disconnects; designing for these early avoids last-minute change orders. After installation, inspections verify attachment, conductor labeling, grounding, and rapid shutdown behavior. Final utility permission to operate (PTO) unlocks energy production and billing adjustments.

Maintenance is straightforward but not nonexistent. Most rooftops clean themselves via rain, but dry, dusty climates may benefit from gentle rinses during cool hours. Avoid abrasive tools and hard water spotting; safety comes first—if access is risky, hire help. Snow typically slides off framed modules at modest tilt, though a long-handled soft brush can hasten clearing if necessary. Monitoring portals flag production changes that might indicate tripped breakers, shading changes from new growth, or inverter faults. Keep records of serial numbers, warranties, and installation photos for future service.

Final takeaways for different readers:

– Homeowners: Align system size with usage, confirm roof longevity, and favor equipment that eases service and monitoring.

– Property managers: Standardize specs across buildings, track PR and downtime, and plan budgets for inverter replacements and occasional roof work.

– Small businesses: Consider time-of-use tariffs, on-site load shifting, and potential tax advantages to maximize return.

In short, a thoughtful design matched to your site and goals turns solar from a hopeful idea into a durable asset. Prioritize roof readiness, sensible layouts, clean electrical design, and clear permitting paths. With those in place, the sunlight you capture translates into dependable kWh, steadier bills, and progress toward your sustainability targets—quietly, day after day.